LJ250IG-CNC

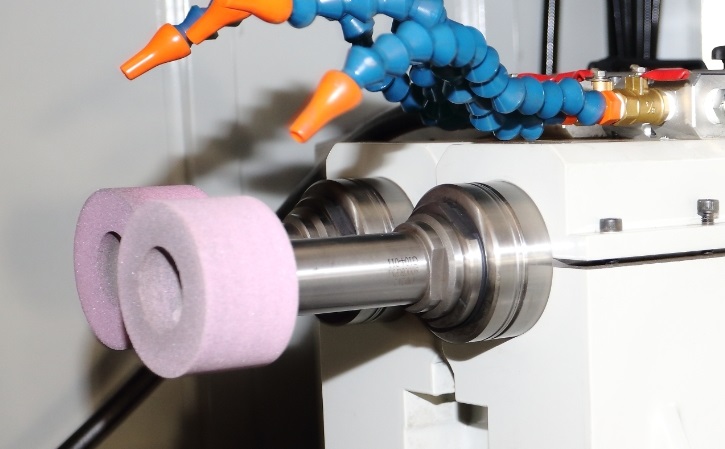

CNC Dual-Axis Inner Cylindrical Grinder

The LJ-250IG Series with CNC control and dual spindles ensures precise ID and face grinding.

Ideal for Ø15mm~150mm cylindrical and tapered bores, it offers flexibility for diverse precision tasks.

Features

The LJ-250IG Series with CNC control and dual spindles ensures precise ID and face grinding.

Multi-Fixture Compatibility–Adapts to various workpiece clamping needs

CNC Intelligent Precision Control

Specification

| Grinding Capability | |

|---|---|

| Max Grinding Length | 250mm |

| Max Grinding Inner Diameter | φ15~φ200mm |

| Max Grinding Weight | 50kg |

| Heights of Center | 185mm |

| Wheelhead | |

| Grinding Wheel Speed | Standard Type:15,000/20,000/30,000RPM |

| Grinding Wheel Speed | Heavy Duty Type:8,000/10,000RPM |

| Grinding Wheel Speed | High Speed Type:40,000/50,000RPM |

| Headstock | |

| Main Spindle | 40~360RPM |

| Spindle Swing Angle | ±45° |

| Spindle Taper | MT#4 |

| Worktable | |

| Worktable Stroke | 400mm |

| Max Table Moving Speed | 5000mm/min |

| CNC Control Axial | |

| Grinidng Wheel Axial (ID Grinding) | X1 |

| Grinding Wheel Axial (End Face Grinding) | X2 |

| Worktable Moving Axial | Z |

| Work Spindle Axial | C |

| Machine Size | |

| Machine Dimensions (LxWxH) | |

| Machine Net Weight | 4000kg |

Specifications are for reference only. Final specs are based on actual design. LIH JAAN reserves the right to change without notice.

Application

Video

Standard Accessories

- Flat Belt

- Wheel Dressing Attachment

- Wheel Connection Bar

- Diamond Dresser #10

- X Axis Optical Scale (FAGOR:NC/CNC)

- 3 Jaw Chuck and Flange

- Heavy Duty Type 3 Jaw Chuck and Flange

- 3 Point Steady Rest

- Coolant Tank

- Coolant Splash Guard

- Tool box

- Work Lamp

Optional Accessories

- 3 Jaw Chuck and Flange

- Heavy Duty Type 3 Jaw Chuck and Flange

- Coolant Filter-Magnetic Type

- Coolant Filter-Fabric Type

- Z Axis Optical Scale

- Customized Fixture / Carrier